Corrugated sidewall belts are ideal for transporting bulk goods efficiently on uphill and downhill gradients.

FLEXOWELL – Faster, cleaner, economical

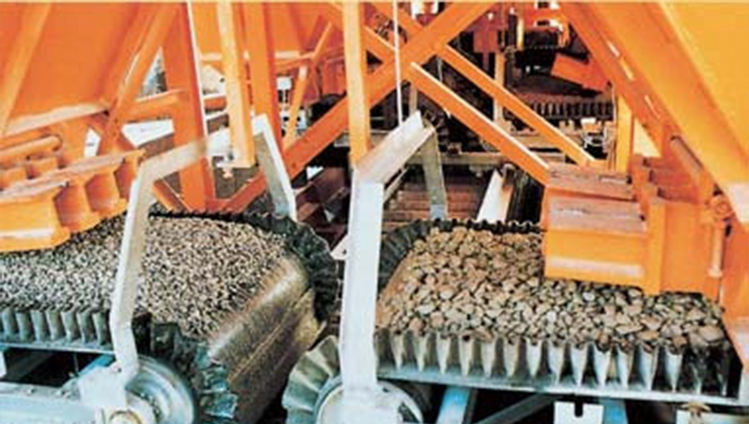

Flexowell conveyor belts are designed for horizontal, steep inclined and vertical handling of all kinds of bulk materials – from coarse-size coal and ore, rock, coarse sand or fertilizers. Lump sizes varying from powdery, floury material up to material with material size 400 mm (16"). Materials can be carried over 500 m (1,640') in vertical lift with capacities up to 6,000 t/h. Flexowell conveyor belts are supplied in standard black rubber quality of high abrasion resistance. In addition, other qualities such as heat and oil resistant or flame retardant rubber can be supplied.

Applications

- Coal and wood-chip fired power stations

- Underground mining (coal and ore)

- Shaft conveying for tunnelling and underground mining

- Steel industry

- Ship loading and unloading, ship to ship loading

- Sand preparation in foundry plants

- Silo feeding

- Slope conveying in openpit mining

- Waste recycling, soil purification and water treatment

- Handling of large material flows in the horizontal path

Product range

In order to grant optimal solutions for each application there are:

- five different types of base belts with different carcasses,

- wide range of different cleats and sidewalls up to 600 mm (23.6 inch) in height,

- six rubber qualities which are used also for sidewalls and cleats.

Base belts are available with following carcasses :

- Type XE: light duty Flexowell applications only.

- Type XOE: reduces transverse deflection at wheels and stub idlers.

- Type XDE: for medium and heavy duty special applications only.

- Type XUE: reduces transverse deflection at return strand when carried on discs or inside idlers.

- Type XST: heavy duty applications used for belt tension above 1000 N/mm with ES-Type Flexowell sidewalls up to 630 mm (24.8 inch) and cleats up to 600 mm (23.6 inch).

The FLEXOWELL technology holds all inclined and vertical continuous transport records in the bulk material handling industry …

- Over 60,000 installations worldwide

- Most experience: FLEXOWELL technology in practical operation since 1964

- Highest performance: 276 m (905 ft) vertical up to 2.000 t/h (2,204 st/h)

- Vertical conveying: up to 500 m (1,640 ft) possible

- Widest belts: 2.4 m (7.87 ft)

- Highest tensile strength: up to 8.600 N/mm (4,910 PIW)

- Lowest belt elongation: by means of high tensile fabric or steelcord members

- Highest sidewalls: up to 630 mm (24.8 inch)

- Highest cleat profiles: up to 600 mm (23.8 inch)

- Worldwide sales: in 45 countries

Outstanding features

- Quick installation

- Reduced number of transfer points

- Long service life

- Reduced power requirements

- Quiet running

- Reduced maintenance

- Environmentally friendly

One of the main advantages of the FLEXOWELL belt is that cross rigid base belts can be deflected from the horizontal to an incline or vertical and back again without bowing or sagging.